信息来源于:互联网 发布于:2022-04-15

The instrument should be placed in a clean and dry room (room temperature 20°C±5°C, humidity below 60%) to avoid surface contamination of optical parts, rust of metal parts, and dust and debris falling into the motion guide rail, which will affect the performance of the instrument.

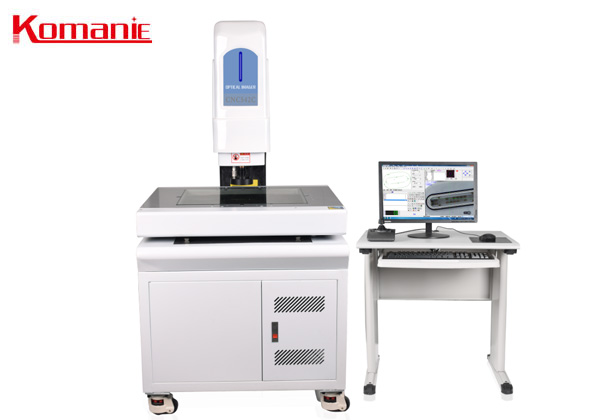

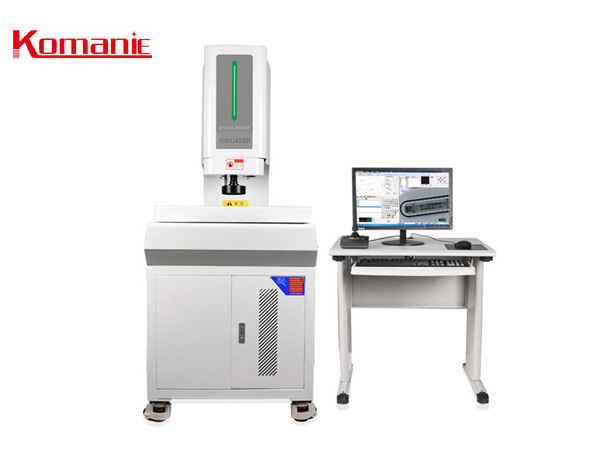

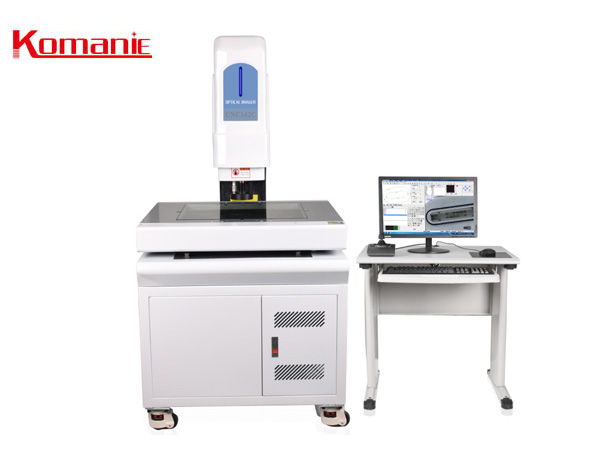

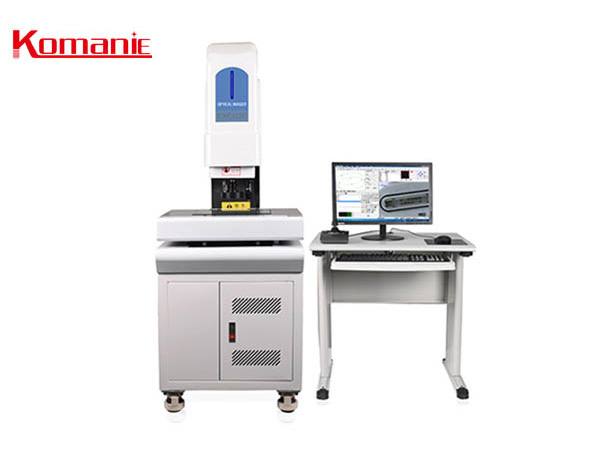

Can a two-dimensional measuring instrument measure height? How much accuracy can be achieved in general? The two-dimensional measuring instrument, also known as the image measuring instrument, is a non-contact optical measuring machine used to measure the two-dimensional plane size of the product, so the data of the two-dimensional measurement is generally in the plane. However, some products are special. In addition to measuring the size in the two-dimensional plane, it is also necessary to measure the height of the product. Can the two-dimensional measuring instrument be competent at this time?

What is the main function of the calibration of the side head of the image measuring instrument? Generally speaking, the calibration of the side head is mainly the index value of the length of the side head, the axial force value of the side head stylus and the half meridian of the side head. The calibration of the side head and standard ball of the two-dimensional imager has a key effect in the whole process of accurate measurement. The application of the side head can automatically align the product workpiece, accurately measure during the sequence, and check after the sequence, which can not only reduce the preparation of the product workpiece in advance time, improve the usable time, and reduce the damage to the product workpiece caused by manual alignment deviation.

What is the principle of the probe calibration of the image measuring instrument? Probe calibration is mainly performed using standard spheres. The diameter of the standard ball is between 10mm and 50mm, and its diameter and shape error are calibrated (the standard ball configured by the manufacturer has a calibration certificate). Before the probe is calibrated, the probe needs to be defined. According to the requirements of the measurement software, select (input) the probe, probe, extension rod, stylus, standard ball diameter (the actual diameter value after calibration of the standard ball), etc. The software needs to input the distance from the stylus to the center of the probe head, and at the same time, it needs to define the probe number that can distinguish its different angles, positions or lengths.

For image measuring instruments, the constant temperature environment is very important to the measurement accuracy. Generally, the normal measurement temperature fluctuates two degrees up and down 20 degrees Celsius, and the reference grating scale is also corrected by 20 degrees Celsius. The measurement accuracy is only reliable when the temperature is at this point. However, the temperature in the computer room is changing all the time, and the temperature of each component is also different. So in this changeable temperature, how can the image measuring instrument reduce the influence of temperature?

As a precision measuring instrument, the automatic image measuring instrument can prolong the service life of the machine, ensure the accuracy and reduce the failure rate if it is maintained and maintained in time. What should I pay attention to after the automatic image measuring instrument measurement?

What are the measurement errors of image measuring instruments? The measurement error of the image measuring instrument refers to the error inherent in the image measuring instrument itself. The errors caused by the instrument are multi-faceted, and errors may occur at all stages of the design, manufacture and use of the instrument, which are called the principle error, manufacturing error, and operation error of the measuring instrument.

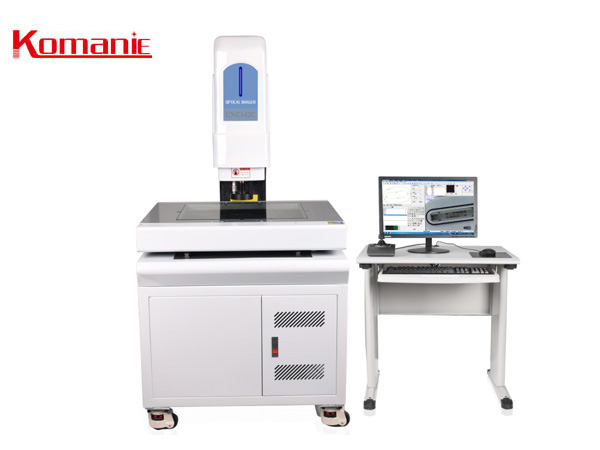

What are the main points to understand the overview of automatic image measuring instrument? Fully automatic image measuring instrument, it can conveniently and quickly perform 3D coordinate measurement and SPC result classification, and meet the increasingly prominent requirements of modern manufacturing for dimensional inspection: higher-speed, more convenient, and more accurate measurement needs to solve the development of the manufacturing industry Another bottleneck in technology.

What are the steps for the calibration of the secondary element measuring instrument? The two-dimensional measuring instrument product not only measures the two-dimensional plane size, but also detects the steps and depth of the product. The accuracy of angle detection has always been our consideration. The two-dimensional image measuring instrument can measure the regression line with small deviation.

How to solve these problems when using the image measuring instrument? Image measuring instrument is a new type of high-efficiency precision measuring instrument, which is widely used in machinery manufacturing, electronics, automobiles, aerospace and other industries. It can be used for online inspection of the size, shape and mutual position of components, and can also be applied to scribing, centering holes, lithography integrated circuit alignment, etc. Because of its strong versatility, large measurement range, high precision, good performance, strong real-time performance, and the ability to connect with flexible manufacturing systems, it has been widely used.

About us

- Company exhibition - Company team building - Factory strength - Partner - CertificationsProduct Center

- Optical Image Measuring Instrument - Environmental equipment - Mechanical equipmentNews center

- Company news - Common problem - Industry information

Mobile website

Dongguan Komanie Precision Optical Measurement Technology Co., Ltd. © Copyright Technical Support: Wangyi Technology [GMAP] [BMAP] [Management] [Back to top]