信息来源于:互联网 发布于:2022-04-15

How does the manual image measuring instrument perform scanning wavelength optical measurement? The use of one or more optical power meters in combination with a Tunable Laser Source (TLS) enables optical power versus wavelength measurements. This type of measurement is often used to determine the ratio of the input power to the output power of the device under test, which is called insertion loss and is measured in dB. When the TLS tunes the wavelength within the selected range, the power meter will periodically sample the power at the specified number of measurement points.

How does the image measuring instrument perform moisture-proof skills? The weather in southern my country is relatively humid, with a lot of rain and high humidity. There are frequent heavy rainstorms in many places. In such a humid environment, remind all users of the video measuring instrument to pay attention to maintaining your video measuring instrument. In particular, do a good job of moisture-proof measures. In order to avoid many failures during use. We know that the image measuring instrument is a precise measuring instrument that has requirements for the environment.

The video measuring instrument has a powerful detection function, which can detect multiple complex parameters of the workpiece, thereby providing quality assurance for production. In the process of inspecting some workpieces, sometimes it is necessary to use a 2.5-dimensional image measuring instrument to measure the height of the workpiece. What methods can the 2.5-dimensional image measuring instrument measure the height?

What are the software classifications of the two-dimensional measuring instrument? The two-dimensional measuring instrument is also called a two-dimensional measuring instrument, or an image measuring instrument and a video measuring machine. It is used to measure the size of products and molds. The measurement elements include position, concentricity, straightness, contour, and roundness. and datum-related dimensions, etc. There are many types of two-dimensional measuring instrument software in the domestic market, and there are mainly the following two types in terms of functions:

What are the software classifications of the two-dimensional measuring instrument? The two-dimensional measuring instrument is also called a two-dimensional measuring instrument, or an image measuring instrument and a video measuring machine. It is used to measure the size of products and molds. The measurement elements include position, concentricity, straightness, contour, and roundness. and datum-related dimensions, etc. There are many types of two-dimensional measuring instrument software in the domestic market, and there are mainly the following two types in terms of functions:

When we usually use the image measuring instrument to measure the workpiece, we will ignore the ground flatness of the place. Under normal circumstances, if the image measuring instrument requires measurement in an absolute level environment, the data will achieve very accurate results. However, due to various reasons, the absolute level working environment is not easy to find. It is also impossible for us to spend a lot of resources in order to find an absolute level of measurement environment. So for the relatively uneven measurement environment, how can the image measuring instrument ensure the accuracy in the vibration process?

What problems should be paid attention to when using the two-dimensional measuring instrument? How to maintain it? Friends who operate the two-dimensional measuring instrument know that if some details are not paid attention to during the operation and use of the two-dimensional measuring instrument, the service life of the two-dimensional measuring instrument will be reduced, or the accuracy of its measurement results will be inaccurate. So what details should be paid attention to in the process of using the two-dimensional measuring instrument? Pay attention to the following details.

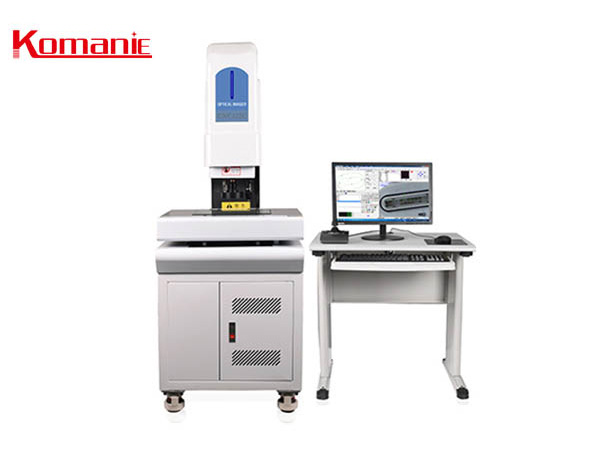

How to understand the development trend of automatic image measuring instrument? The automatic image measuring instrument has promoted the image measuring technology to a new stage. It has the characteristics of high intelligence and automation, which can make the whole measuring process simple and easy. Through simple programming, the automatic image measuring instrument can easily learn all the practical operation process of the operator. Combined with its automatic focus and area search, target locking, edge extraction, and fuzzy operation of matching points to achieve artificial intelligence, it can automatically correct the workpiece caused by the workpiece. The offset caused by the difference and the position difference realizes precise point selection with high-precision repeatability.

Product advantages of automatic image measuring instrument What maintenance should be paid attention to? Fully automatic image measuring instrument It can solve the problem of appearance dimension measurement of printed circuit board (PCB), and has 2D precision measurement at the same time. It also has the characteristics of high speed and precision, and can perform multiple functions on a single machine, greatly reducing the cost of repeated purchase of machines and the waste of empty space. SOV series is a general-purpose 3D precision measurement and program editing system. The measurement objects can be PCB boards, negatives or other objects with 2D properties.

Which industries have the coordinate measuring machines of automatic image measuring instruments developed and applied to? The emergence of the coordinate measuring machine is the historical necessity of the development of industrialization. On the one hand, it is due to the development of high-efficiency processing such as automatic machine tools and CNC machine tools, and the processing of more and more complex-shaped parts requires fast and reliable measuring equipment; on the other hand, due to electronic technology, computer technology, CNC technology and precision The development of processing technology provides the technical basis for it. The appearance of the coordinate measuring machine makes it possible to change the measuring instrument from manual mode to modern automatic measurement.

About us

- Company exhibition - Company team building - Factory strength - Partner - CertificationsProduct Center

- Optical Image Measuring Instrument - Environmental equipment - Mechanical equipmentNews center

- Company news - Common problem - Industry information

Mobile website

Dongguan Komanie Precision Optical Measurement Technology Co., Ltd. © Copyright Technical Support: Wangyi Technology [GMAP] [BMAP] [Management] [Back to top]