Optical image measuring instrument high-end automatic machine DBM-4030P

P-type automatic imager is a new generation of high-precision, ultra-high-definition, high-speed measurement equipment independently developed by our company, which can realize high-efficiency and high-precision measurement of large quantities of workpieces, and is suitable for detection and quality...

Optical Image Measuring Instrument - Large Field of View

KS type fast measuring instrument is the latest generation of large-view spliced CNC fast measuring instrument independently developed by our company, which can realize high-efficiency, high-speed and high-precision measurement of large-scale full inspection or large-sized workpieces. This instrument is...

Optical Image Measuring Instrument Manual Machine DBC-2010C

C-type manual imager is the company's standard manual imager, mainly for plane 2D or 2.5D measurement, including point, line, circle, arc, rectangle and other geometric elements and the length, angle, contour shape of parts , surface shape, etc. 3D auxiliary measurement can also be done after adding...

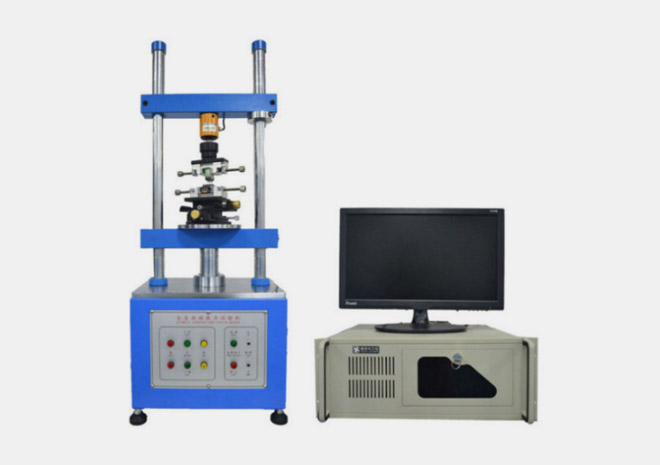

Optical Image Measuring Machine Automatic 4030C

The laser displacement meter using the triangular reflection method irradiates a strip-shaped laser to the surface of the target. By using CMOS to receive the change of its reflected light, the contour (cross-sectional shape) such as height, height difference, and width can be measured in a non-contact...

Precise measurement

Precise measurement Improve efficiency

Improve efficiency Safe and reliable

Safe and reliable Good reliability

Good reliability

R&D, manufacturing, sales

High precision and high stability

Purchase price concessions

1 year warranty fast after sale

NEWS CENTER

Follow us for more non-standard equipment industry informationAbout us

- Company exhibition - Company team building - Factory strength - Partner - CertificationsProduct Center

- Optical Image Measuring Instrument - Environmental equipment - Mechanical equipmentNews center

- Company news - Common problem - Industry information

Mobile website

Dongguan Komanie Precision Optical Measurement Technology Co., Ltd. © Copyright Technical Support: Wangyi Technology [GMAP] [BMAP] [Management] [Back to top]